You are working on a piping project and run into a common problem. You need to connect a small pipe to a larger one. How do you make that connection secure and reliable without a complicated setup?

That is exactly where reducing threaded flanges come in. They are a simple, effective solution for changing pipe size in a system. This guide will walk you through what they are, how they work, and when to use them.

We focus on giving you clear, accurate information you can trust. Our team has years of experience in the piping industry, and we are committed to helping you find the right components for your job.

What is a Reducing Threaded Flange?

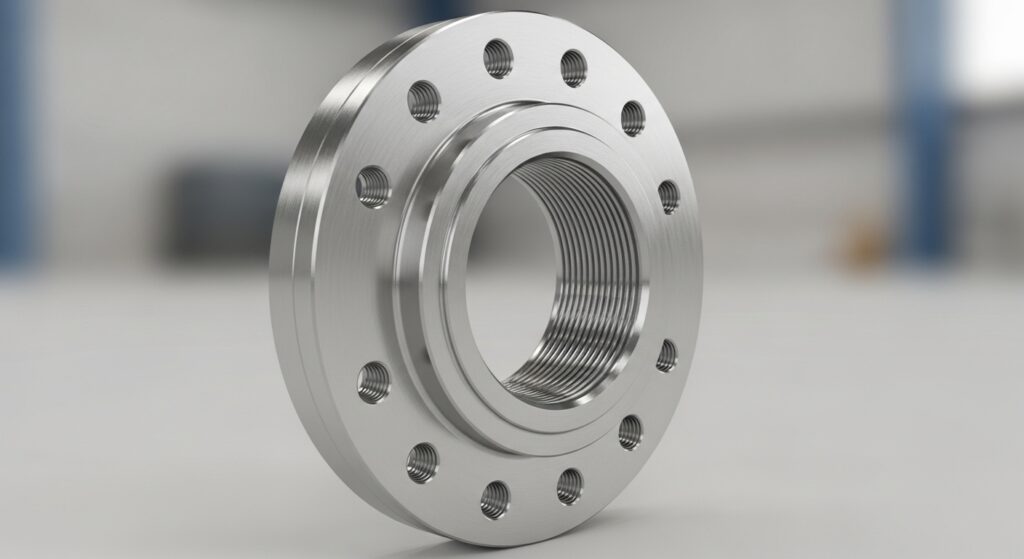

Think of a reducing threaded flange as a two-in-one fitting. It combines a reducer and a threaded flange into a single, solid piece.

Here is a breakdown of its two main jobs:

Reducer Function: The bore (the hole through the center) is two different sizes. One end is smaller to fit a small pipe, and the other is larger for a bigger pipe.

Threaded Flange Function: The smaller bore has internal threads (usually NPT). This allows the flange to screw directly onto the external threads of a pipe, no welding required.

So, instead of buying a separate reducer and a separate flange, you get one compact unit that does both jobs. This makes threaded pipe flanges like these a popular choice for many applications.

How Do Reducing Threaded Flanges Work?

Installing one of these flanges is straightforward. A quick tip: always use a proper pipe sealant on the threads to prevent leaks.

Screw It On: Apply sealant to the male threads of the smaller pipe. Then, screw the reducing flange onto it by hand.

Tighten: Use a wrench to tighten the flange. Be careful not to over-tighten, as this can damage the threads.

Bolt It Up: Align the large face of the flange with a matching flange on the larger pipe. Place a gasket in between, insert the bolts, and tighten them down.

And that is it. You have now created a secure transition between two different pipe sizes. For a deeper look at all the types available, you can explore the full range of Threaded Flanges at Texas Flange.

Key Advantages: Why You Might Choose One

These flanges are not the answer to every problem, but they excel in specific situations.

Easy and Fast Installation: This is their biggest advantage. Since no welding is needed, you save a lot of time and labor.

Ideal for Tight Spaces: They are very compact. In cramped areas where there is no room for multiple fittings, a single reducing flange is the perfect solution.

Easy Maintenance: If you need to disconnect the line for cleaning or inspection, you can simply unscrew it.

Cost-Effective: For small-bore, low-pressure systems, they are often the most affordable option.

Important Limitations to Consider

Now, let us talk about the “when not to use it” part. Being honest about a product’s limits is part of providing a trustworthy service.

Avoid High Vibration: Threaded connections can loosen over time if the pipe vibrates a lot. For those jobs, a welded connection is a much safer bet.

Not for Extreme Service: We do not recommend them for very high-pressure systems or for temperatures that cycle up and down frequently. The threads can be a stress point.

Watch for Galling: When installing stainless steel threaded pipe flanges, the threads can sometimes gall and seize. Using an anti-seize compound is a simple fix for this.

Pipe Thinning: The threading process removes material from the pipe wall. You must make sure the remaining pipe wall is still thick enough to handle the pressure.

Where Are Reducing Threaded Flanges Used?

You will find these flanges in many industries for specific, non-critical connections. They are common in:

Instrument and gauge lines.

Plant water and cooling systems.

Chemical injection points.

Oil and gas utility stations.

HVAC and fire protection sprinkler lines.

Understanding Threaded Flanges Dimensions

Getting the size right is critical. Threaded flanges dimensions are standardized under ASME B16.5, which covers things like the outside diameter, bolt hole count, and bolt circle.

But one thing to consider is the thread standard. In the USA, the most common type is NPT (National Pipe Taper). It is crucial that your pipe threads match the flange threads. You cannot mix NPT with other standards like BSPT. Always confirm the thread specification before you order. You can find detailed threaded flanges dimensions charts on the Texas Flange website.

Frequently Asked Questions

What is the main difference between a threaded flange and a weld neck flange?

The connection method. A threaded flange screws onto a pipe, while a weld neck flange is welded on. Welded connections are stronger and better for high-stress services, but threaded connections are faster and allow for disassembly.

Can I use a reducing threaded flange for a steam line?

It is generally not recommended. Steam lines often have high temperature and pressure, which can cause threaded joints to leak. A welded reducer and flange is the standard, safer choice for steam service.

What materials are reducing threaded flanges made from?

They come in many materials to match your piping system. Common ones include ASTM A105 (carbon steel), A182 F304/F316 (stainless steel), and various alloy materials for corrosive environments.

How do I prevent a threaded flange connection from leaking?

Use a high-quality pipe thread sealant or Teflon tape. Ensure the threads are clean and undamaged. Tighten the flange properly, but avoid over-tightening, which can strip the threads.

Where can I find a price for a specific reducing threaded flange?

We recommend contacting a supplier directly with the exact size, material, and pressure class. For accurate and competitive pricing, you can request a quote from Texas Flange.

What does a “Class 150” rating mean on a flange?

This is the pressure rating. A Class 150 flange is designed to handle a certain maximum pressure at a given temperature. The rating changes with temperature, so always check a pressure-temperature chart for your specific application.

Need a Reliable Flange Supplier?

Choosing the right component is only half the battle. You also need a supplier you can count on for quality and reliability.

At threadedflange.com, we partner with trusted industry leaders like Texas Flange to ensure you get products that meet strict ASTM standards. Whether you are an engineer finalizing a spec sheet or a procurement manager sourcing materials, having a dependable partner matters.

Have a question about your project? Our network of experts is here to help you make the right choice. Contact us today for more information or to get a quote for your specific needs.